Weekly Advanced Technologies〔57〕

Weekly Advanced Technologies〔57〕| What Are the Strong - yet - Flexible Metal Alloys Like? | "See through" Cells, AI Aids in Nanomedicine R&D

The intelligent deformation of aircraft, robots, super-strong artificial muscles, and other cutting-edge future technologies hinges on the development of a new class of metal materials. In a recent breakthrough, scientists from Xi'an Jiaotong University have engineered a metal alloy that harmoniously merges the traits of ultra-flexible polymer materials with the formidable strength of ultra-high-strength steel, thereby providing a robust foundation for these emerging fields.

CHEN Chunyin, WANG Yalin from the National Center for Nanoscience and Technology, and ZHANG Kai from the Institute of High Energy Physics of the Chinese Academy of Sciences

have jointly developed a machine learning-based analysis technology for synchrotron radiation hard X-ray nano-CT imaging data (DL-HXT). This technology can "see through" cellular structures and intracellular nanoparticles, and automatically and systematically segment, identify, and statistically analyze different structures.

Based on the weekly diary of technology provided by the daily list of the NCSTI online service platform, we launch the column "Weekly Advanced Technologies" at the hotlist of sci-tech innovation. Today, let's check out No.57.

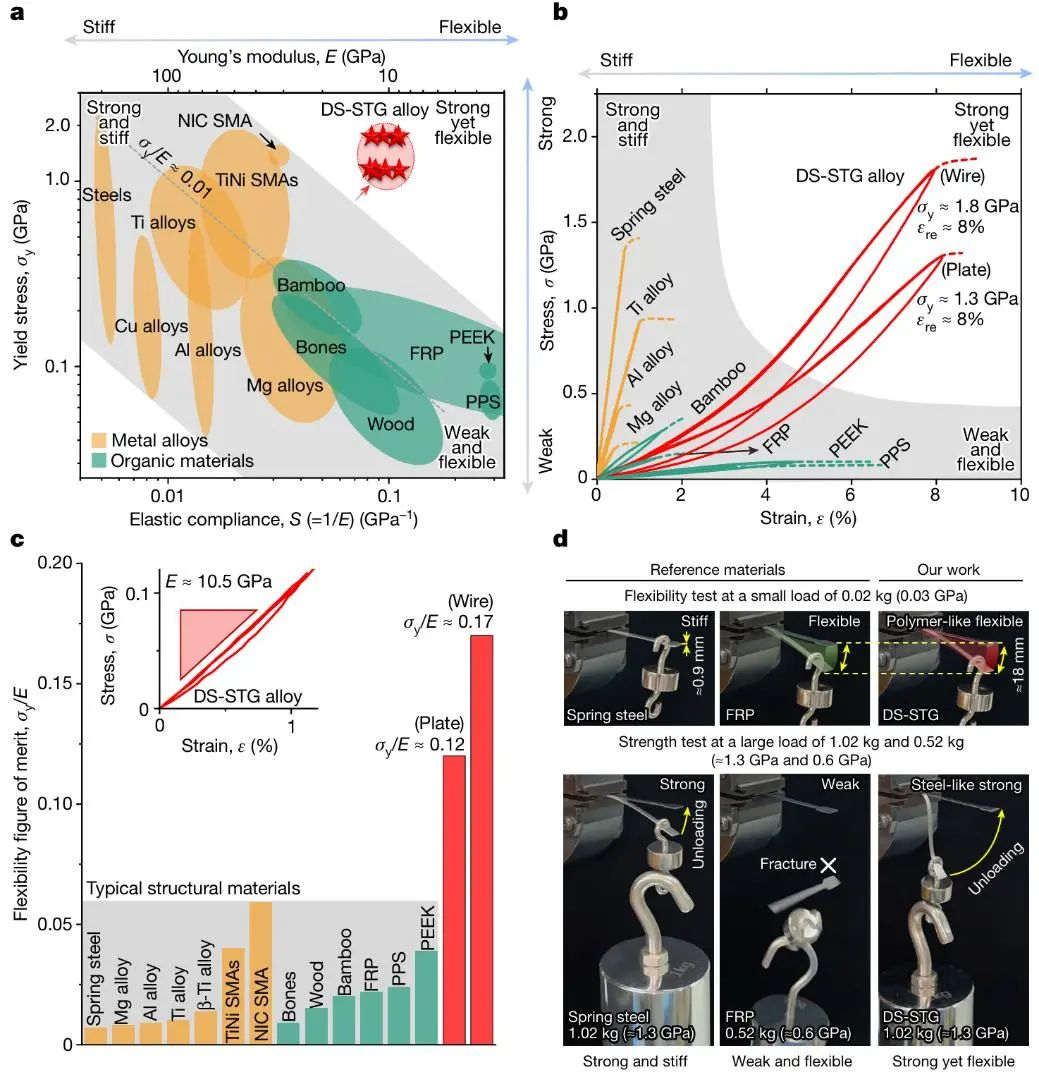

1. Nature丨What Are the Strong - yet - Flexible Metal Alloys Like?

Future technologies such as smart deformable airplanes and super-strong artificial muscles for robots are in dire need of a new class of metallic materials that are as strong as ultra-high-strength steel and as flexible as polymers. However, this engineering technology eagerly awaited “both strong and flexible” properties are not allowed by the current physical principles of nature. This is because high strength requires strong atomic bonds, but strong atomic bonds result in low flexibility. Therefore, the previous high-strength materials such as high-strength steel strength is very high (strength higher than 1 GPa), but its flexibility is very low (modulus of elasticity or stiffness coefficient of up to 200 GPa); and polymers are highly flexible (modulus of elasticity is as low as 10 GPa or less), but its strength is also very low (mostly less than 0.2 GPa).

Recently, the Frontier Institute of Science and Technology, Xi'an Jiaotong University and the State Key Laboratory for Mechanical Behavior of Materials have joined forces to create a scalable exotic metal. Building upon the Center's foundational research on strain glasses, they have achieved a distinctive strain glass state, DS-STG, characterized by the presence of two martensitic "seeds" within a commercial Ti-50.8Ni alloy. This was accomplished through a three-step thermomechanical treatment process that can be scaled up for production. The resulting alloy exhibits ultra-high strength due to deformation strengthening (1.8 GPa) and exceptional flexibility via the invisible core growth of martensitic "seeds" (10.5 GPa).

The alloy not only boasts ultra-high strength from deformation strengthening (1.8 GPa) but also demonstrates ultra-high flexibility (ultra-low modulus of elasticity of 10.5 GPa) and highly reversible deformation (8%) through the growth of martensitic "seeds" without nucleation. These properties are stable across a broad temperature range from -80°C to +80°C, and the metal alloy shows remarkable fatigue resistance under significant strains. These outstanding characteristics are anticipated to enable the alloy to play a crucial role in future technologies such as deformable vehicles, super robots, and artificial organs.

2. ACS Nano丨"See through" Cells, AI Aids in Nanomedicine R&D

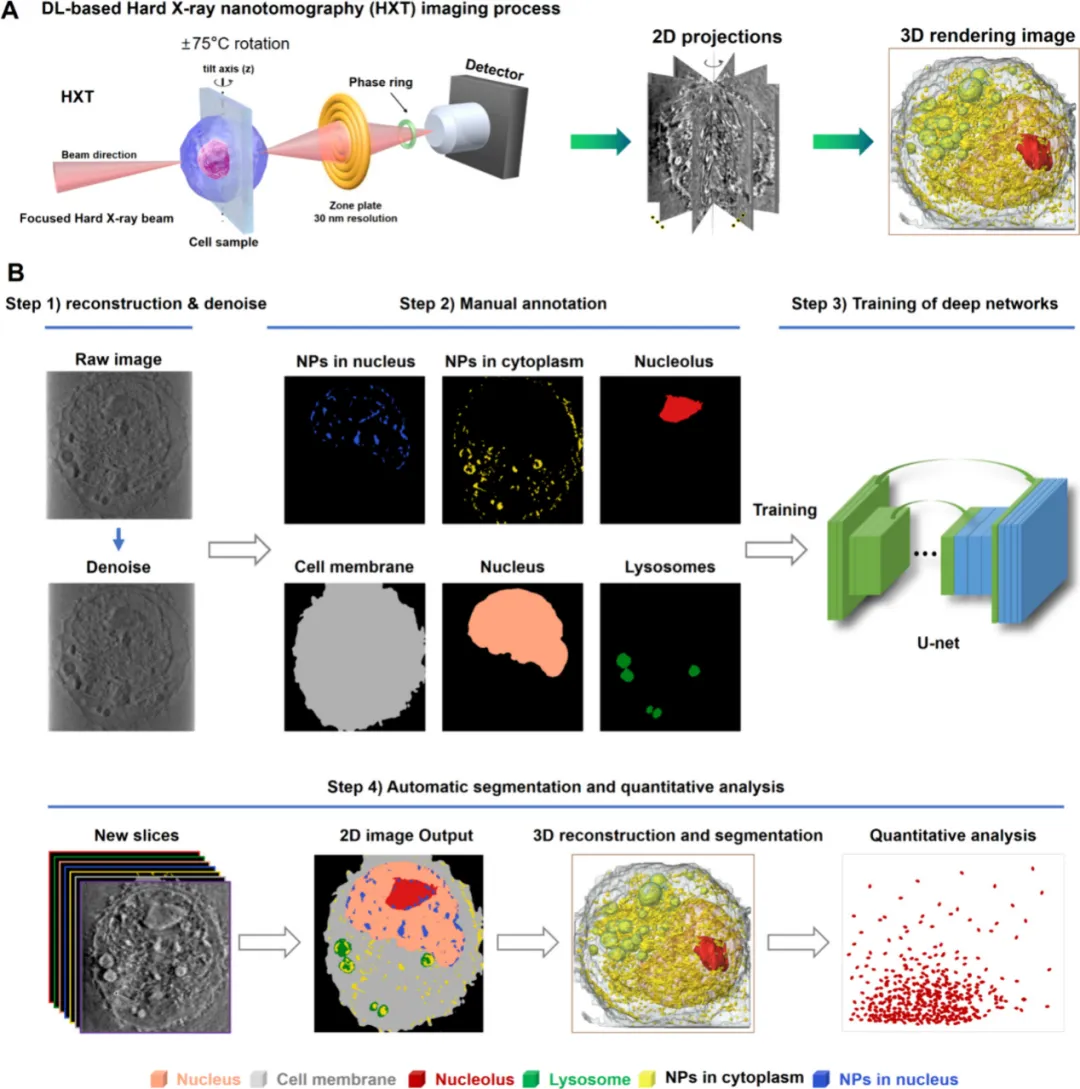

DL-HXT imaging analysis method flow

Synchrotron radiation hard X - ray nano - resolution CT imaging, which features high spatial resolution and three - dimensional imaging capabilities, is able to directly observe the three - dimensional spatial distribution behavior of self - assembled nanoparticles at the subcellular level. This is of great significance for the research and development of nanomedicine, as well as for the investigation of the pharmacological and toxicological properties of nanomedicines. Nevertheless, synchrotron radiation hard X - ray nano - resolution CT imaging still encounters challenges when imaging the "massive" self - assembled nanoparticles within cells. It is difficult to identify small - scale intracellular particles and segment the images, and the absence of a batch - standardized CT data processing procedure affects the accurate and effective analysis of the "massive" data.

CHEN Chunyin, WANG Yalin from the National Center for Nanoscience and Technology, and ZHANG Kai from the Institute of High Energy Physics of the Chinese Academy of Sciences

have jointly developed a machine learning-based analysis technology for synchrotron radiation hard X-ray nano-CT imaging data (DL-HXT). DL-HXT technology can automatically identify the cell's own structures, including the nucleus, as well as intracellular nanoparticles, and perform automated, standardized segmentation identification and statistical analysis for different structures.DL-HXT data analysis technology also provides a batch data analysis method for three-dimensional, nano-resolved, label-free intracellular nanoparticle imaging. The analysis results visualize the interactions between intracellular nanoparticles as well as the spatial distribution of nanoparticles within the cell, aggregation behavior, and aggregate morphology characteristics.

This work offers a convenient, reliable, and innovative analytical method for clarifying the nanoparticle assembly mechanism at the subcellular level, exploring the interactions between nanoparticles and organelles as well as those between different organelles. Moreover, it provides a new evaluation tool for the subsequent pharmacological studies of self - assembled drugs and the development of novel nanodrugs.

Columnist: Li Xiaoxiao

Translator: Liu Kaiyuan