Qbeam's 3D printing equipment boots aerospace and medical device development

The Qbeam S350 and Qbeam S600 devices, independently developed by Beijing Qbeam, which is based in Beijing Economic-Technological Development Area (Beijing E-Town), were selected for the third group of the Major Technical Equipment Catalogue (Units) for 2024 in Beijing.

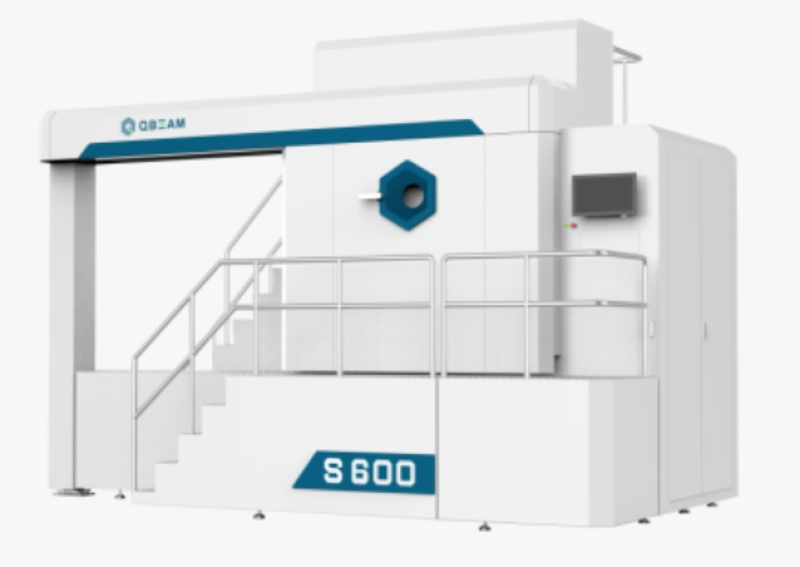

The Qbeam S600 device is the world's first array-type electron beam additive manufacturing equipment and is the first to achieve array-type electron beam 3D printing.

The Qbeam S600 device, independently developed by Beijing Qbeam

These two devices have addressed difficult points in the development of aerospace and medical fields.

The Qbeam S350, with a forming size of 350mm × 350mm × 500mm, supports the printing of various high-performance metal materials such as titanium alloys, high-temperature titanium alloys, high-strength titanium alloys, and aluminum alloys, making it suitable for the aerospace, medical devices and other fields.

The Qbeam S600, developed based on the S350 device, has a forming size of 600mm × 600mm × 700mm and adopts independently developed multi-electron gun array technology. This not only ensures the size accuracy and quality of large-format forming but also achieves high-precision, high-efficiency and low-cost manufacturing of complex titanium alloy components.

The Qbeam S600 has not only become a global pioneer but also set a new record for the largest printing area in commercial electron beam equipment.

Beijing Qbeam is at the forefront of international multi-gun array printing technology. The Qbeam S600 has been put into production and has started production and delivery of cabin segments, rudder components, and integral frame beam structural parts in the aerospace field. The Qbeam S350 has been introduced to the domestic market, printing components for several aerospace companies and achieving production printing of multiple titanium alloy components.