Weekly Advanced Technologies〔88〕

Weekly Advanced Technologies〔88〕丨Breaking New Ground: Hydrogen-Anion Batteries Achieve Full Charge-Discharge Cycle to Illuminate LEDs; AI-Powered Gene Expression Optimization: Beyond Blind Replacement Strategies

Chinese scientists have achieved dual breakthroughs in next-generation battery technology and AI-driven gene optimization. A research team from the Chinese Academy of Sciences developed a novel electrolyte to construct the first rechargeable hydrogen-anion battery—a potential game-changer for future energy storage—marking a critical leap from theory to practice. Meanwhile, in synthetic biology, traditional gene optimization often fails due to overusing high-frequency codons. To address this, researchers created DeepCodon, an AI model that intelligently preserves functionally critical rare codons, dramatically improving exogenous gene expression efficiency. These innovations demonstrate China's growing leadership in cutting-edge energy and biotechnologies.

Based on the weekly diary of technology provided by the daily list of the NCSTI online service platform, we launch the column "Weekly Advanced Technologies" at the hotlist of sci-tech innovation. Today, let's check out No.88.

1. Nature丨Breaking New Ground: Hydrogen-Anion Batteries Achieve Full Charge-Discharge Cycle to Illuminate LEDs

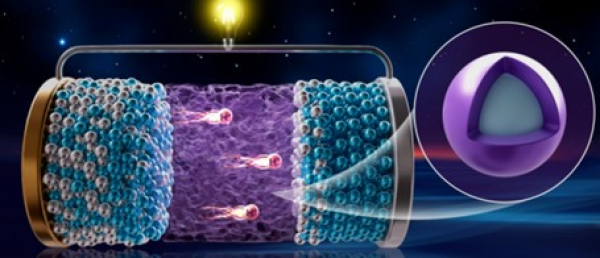

Schematic Diagram of Hydride-Ion (H⁻) Prototype Battery

The research team led by CHEN Ping, CAO Hujun, and ZHANG Weijin at the Dalian Institute of Chemical Physics (DICP), Chinese Academy of Sciences, has achieved a major breakthrough in the development of hydride-ion (H⁻) conductors and batteries.

Hydrogen typically exists in the form of protons (H⁺), atoms (H), or hydride ions (H⁻). Among these, hydride ions are highly reactive and represent a promising energy carrier. A hydride-ion battery stores energy by shuttling H⁻ ions as charge carriers, operating on a principle similar to that of lithium-ion batteries. However, due to the lack of suitable solid electrolyte materials, this technology had long remained at the conceptual stage.

In 2018, the team initiated this research, and in 2023, they proposed the "lattice distortion to suppress electronic conductivity" strategy, successfully developing a room-temperature ultrafast hydride-ion conductor. Building on this breakthrough, they innovatively designed a core-shell composite material: a thin layer of stable but poorly ion-conductive barium hydride (BaH₂) encapsulating highly ion-conductive yet unstable cerium trihydride (CeH₃), forming 3CeH₃@BaH₂. This material exhibits high hydride-ion conductivity, low electronic conductivity, and excellent thermal/electrochemical stability, making it an ideal electrolyte.

Building on this breakthrough, the team has successfully constructed the first hydride-ion (H⁻) prototype battery, employing sodium aluminum hydride (NaAlH₄) as the cathode and cerium dihydride (CeH₂) as the anode. Test results have demonstrated that the cathode achieves an initial discharge capacity of 984 mAh/g and maintains 402 mAh/g after 20 cycles. Through a stacked-cell design, the battery voltage has been elevated to 1.9 volts, successfully powering a yellow LED light and validating its power supply capability. This achievement marks the transition of hydride-ion batteries from "conceptual" to "experimentally verified," opening new pathways for novel energy storage technologies.

2. AI-Powered Gene Expression Optimization: Beyond Blind Replacement Strategies

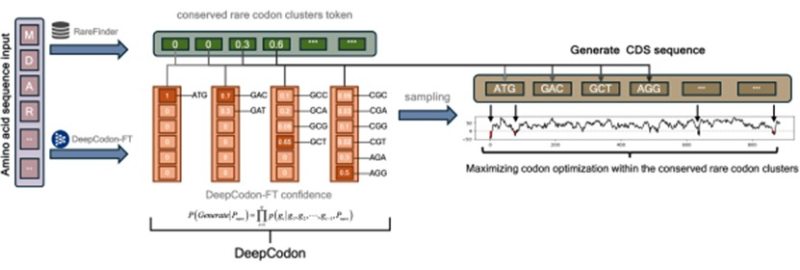

Schematic illustration of DeepCodon's architecture.

In synthetic biology and industrial biomanufacturing, codon optimization serves as a pivotal technique for enhancing the expression levels of heterologous genes in engineered strains. Traditional approaches primarily rely on replacing rare codons with host-preferred high-frequency codons. While this can improve expression, it often disrupts critical "rare codon clusters" within the sequence—structural elements that regulate proper protein folding and translation kinetics. Consequently, such crude optimization may lead to protein misfolding or complete expression failure.

A research team led by JIANG Huifeng at the Tianjin Institute of Industrial Biotechnology, Chinese Academy of Sciences (TIB-CAS) has made new progress in this field by developing DeepCodon, a deep learning-based codon optimization model. The model employs artificial intelligence to learn the codon selection patterns of naturally highly expressed genes, establishing a "translation mapping" from protein sequences to optimal coding sequences. Through large-scale data training combined with fine-tuning using high-expression genes, the generated sequences simultaneously achieve high expression potential and biological rationality.

DeepCodon employs an innovative conditional probability strategy to optimize gene expression while protecting functionally critical rare codons, demonstrating superior performance in E. coli with 9 out of 20 tested genes showing significantly higher expression compared to conventional methods, alongside 10 comparable cases and only 1 slightly lower result. This AI-powered tool has now been implemented as a free online service to support efficient biomanufacturing applications.

3. National Science Review丨Defying Metal Fatigue: New Method Enhances Steel Strength by 26%

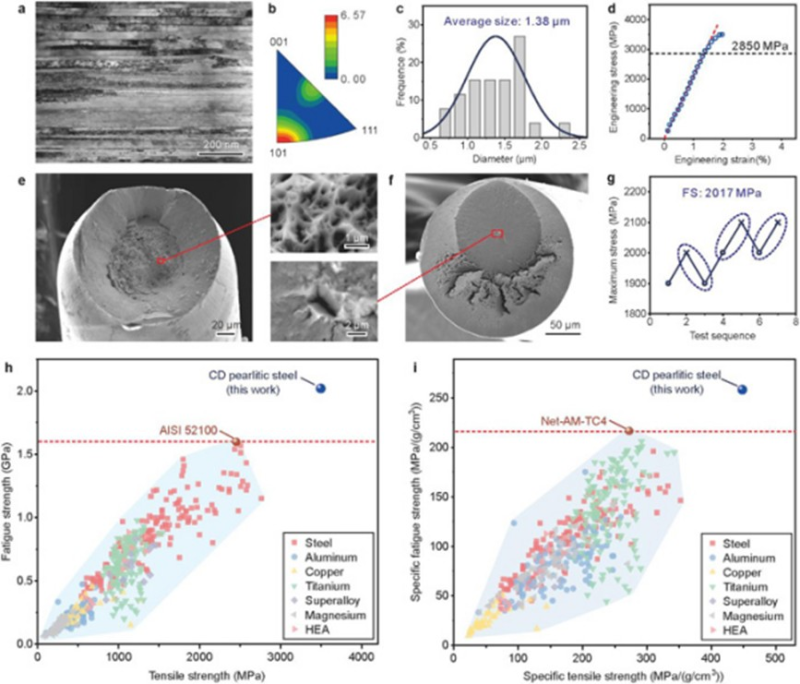

Fatigue-resistant design 'Four Principles' for metallic materials and world-record fatigue strength achieved in cold-drawn pearlitic steel wire

Fatigue strength is a key indicator determining the service life of materials and engineering components. Enhancing this property improves reliability, enables lightweight design, and increases energy efficiency. The research team led by Prof. ZHANG Zhefeng at the Institute of Metal Research, Chinese Academy of Sciences, has made a groundbreaking achievement in metal fatigue resistance. They proposed the "Four Principles" for improving fatigue strength and achieved a tension-tension fatigue strength of 2017 MPa in cold-drawn pearlitic steel wire, surpassing the previous world record (1600 MPa) by 26% and setting the new global benchmark.

The team proposed the "Four Principles" for fatigue-resistant design: high elastic modulus to elevate the theoretical strength limit; "fine, stable, and homogeneous" microstructure to eliminate strength weak zones; minimized inclusions/defects to reduce stress concentration; and excellent tensile properties combining high elastic limit and strain-hardening capability. Based on these principles, the research employed high-elastic-modulus steel, specifically focusing on pearlitic steel with an ultra-fine and stable microstructure. Through cold-drawing, a strong <110> texture was formed while eliminating weakly oriented lamellae, thereby enhancing microstructural homogeneity. By synergistically incorporating solid-solution strengthening, work hardening, and grain-boundary strengthening, the material achieved an ultra-high elastic limit of 2850 MPa and a tensile strength of 3525 MPa, effectively suppressing fatigue crack initiation.

Simultaneously, through ultra-purification smelting and multi-pass drawing, the average inclusion size in the steel wire was reduced to 1.38 μm while retaining a certain strain-hardening capacity, thereby alleviating stress concentration around defects. Ultimately, this cold-drawn pearlitic steel wire not only set a new world record in tension-tension fatigue strength but also improved specific fatigue strength, providing novel theoretical and practical pathways for the design and engineering applications of high-strength materials.