Weekly Advanced Technologies〔85〕

Weekly Advanced Technologies〔85〕丨Apparatus and Method for Autonomous Crop Pollination: Robotic System Designated "GEAIR"

Weekly Advanced Technologies〔85〕丨Apparatus and Method for Autonomous Crop Pollination: Robotic System Designated "GEAIR"

While AI-powered gene editing pioneers a 'Tomato Revolution' in smart pollination – enabling synergistic advancement between crops and agricultural robots – a green breakthrough simultaneously emerges for e-waste: Scientists now engineer enzyme-digestible electronic films using specialized bacteria. This biotech innovation enables eco-friendly recycling of electronics, tackling hazardous substance contamination through biodegradable tech solutions.

Based on the weekly diary of technology provided by the daily list of the NCSTI online service platform, we launch the column "Weekly Advanced Technologies" at the hotlist of sci-tech innovation. Today, let's check out No.85.

1. Cell丨Apparatus and Method for Autonomous Crop Pollination: Robotic System Designated "GEAIR"

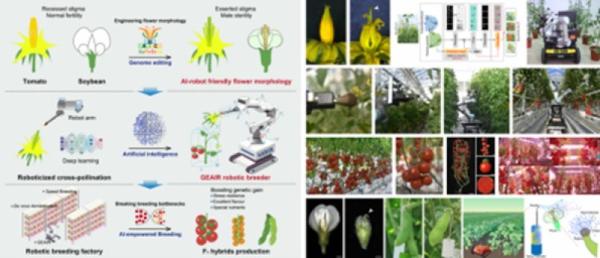

AI-Driven Floral Remodeling & Robotic Collaboration for Automated Hybrid Breeding

The research team led by XU Cao at the Institute of Genetics and Developmental Biology (IGDB) of the Chinese Academy of Sciences proposed the 'synergistic convergence' concept for crop-robot collaborative design. By integrating biotechnology (BT) and artificial intelligence (AI), they created the world's first robot-compatible structural male sterile line. Through targeted gene editing of the GLO2 gene regulating stamen development in tomatoes, they achieved pollen abortion while maintaining naturally exposed stigmas - breaking through the bottleneck of ideal male sterile lines in tomato breeding without compromising yield or seed quality.

Collaborating with the research team led by YANG Minghao at the Institute of Automation, Chinese Academy of Sciences, the scientists developed the world's first autonomous pollination robot "GEAIR". This system integrates deep learning algorithms to achieve 85.1% accuracy in stigma identification, completes pollination per flower in just 15 seconds, and attains a single-mission success rate of 77.6%±9.4%. Capable of continuous all-weather operation with over 95% domestically produced components, it significantly reduces labor costs.

Building upon "de novo domestication" and "rapid breeding" technologies, the team established an intelligent breeding factory that shortens the utilization cycle of wild crop relatives from 5 years to 1 year, enabling efficient cultivation of elite tomato germplasms. The system has been successfully extended to soybean, accelerating the creation of structural male sterile lines while saving 76.2% of pollination time—a breakthrough poised to unlock soybean heterosis applications. This research pioneers the "BAR" model (Biotechnology foundation + AI empowerment + Robotic labor), providing a paradigm for innovating biological breeding and advancing new quality productive forces.

2. Nature Sustainability丨Green Film Technology Enables Controlled Degradation of Electronic Devices: A Sustainable Materials Breakthrough

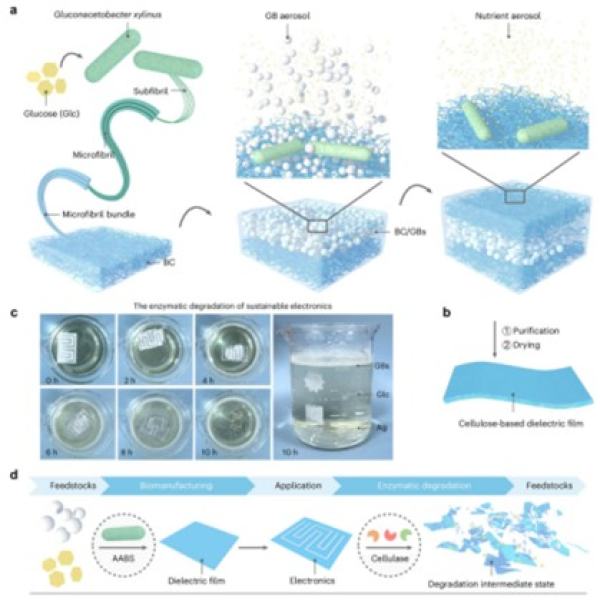

Closed-Loop Bio-Recyclable Cellulose Dielectric Film

A research team led by YU Shuhong, Academician of the Chinese Academy of Sciences and Professor at the University of Science and Technology of China, has developed a closed-loop recyclable cellulose-based dielectric film. This innovation promises to significantly enhance the circular utilization rate of electronic devices while reducing e-waste pollution.

With accelerating electronics replacement cycles, electronic waste challenges have reached critical severity. Current recyclable devices still face three fundamental limitations: unavoidable material degradation during recycling, prohibitively high energy consumption, and partial component discard. Though ideal closed-loop recycling requires zero performance loss in materials across cycles, achieving this has remained elusive in electronic materials – until now."

To achieve this, the research team led by Prof. YU Shuhong innovatively combined aerosol-assisted biosynthesis with specific enzymatic degradation technology to fabricate a novel bacterial cellulose/glass microbeads composite dielectric film. This method converts glucose into high-performance composites under ambient conditions. The resulting film exhibits advantages such as high strength, low dielectric constant, low thermal expansion, and excellent flexibility, outperforming existing organic-inorganic composites. More critically, the film can be completely decomposed into glucose using cellulase enzymes, enabling raw material regeneration and establishing a closed-loop cycle from ‘raw material → product → recycling’.

Experimental results demonstrate that electronic devices based on this film exhibit lower signal transmission losses compared to commercial epoxy resin substrates. Cost analysis suggests substantial commercialization potential, with significant advantages in terms of health and resource-environmental impacts. This strategy has established a new paradigm for sustainable electronic materials design, paving the way for a green circular transition in the electronics industry.

3. Matter丨Flash Upcycling: Instant Transformation of Spent Li-ion Batteries into High-Grade Battery Materials via Rapid Joule Heating

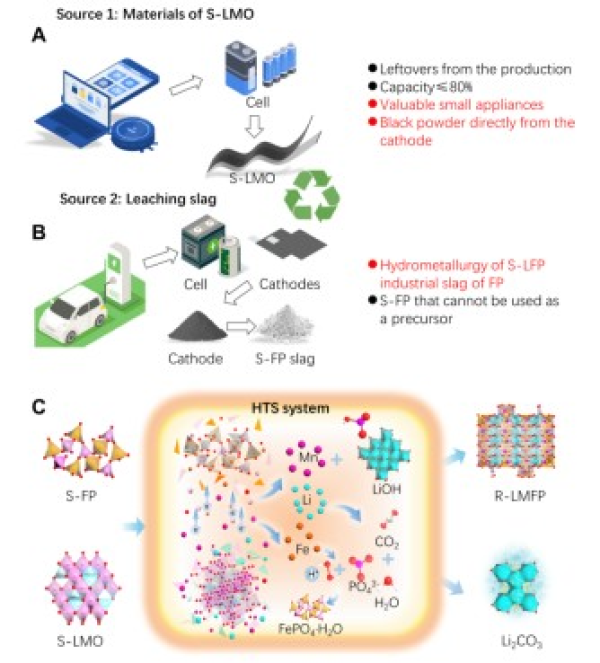

Upcycling Spent Li-ion Batteries and Leaching Residues via High-Temperature Joule Heating

With the rapid development of new energy vehicles, the quantity of retired lithium batteries has surged, making efficient and clean recycling technologies crucial for sustainable industry development. While current mainstream recycling methods focus primarily on metal extraction or direct reparation, they show insufficient attention to the value-added reuse of materials. Joule heating, as a rapid and highly efficient emerging technology, presents a new direction for the upgraded regeneration of retired battery materials.

A research team led by Dr. YUAN Haoran at the Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences partnered with Prof. YANG Jun's team from the Institute of Process Engineering (IPE) to develop a synergistic co-treatment technology. This innovation enables value-added upgrading recycling of both spent lithium manganate (S-LMO) cathode materials and spent ferric phosphate (S-FP) leaching residues derived from spent lithium-ion batteries (SLIBs).

The process employs joule thermal shock treatment coupled with aqueous leaching, achieving >99% lithium extraction efficiency. Through precision-controlled joule heating parameters, it facilitates structural reconstruction and transition metal substitution of manganese/iron elements within S-LMO and S-FP. This single-step synthesis yields regenerated LiMn₁₋ₓFeₓPO₄ (R-LMFP) – a high-energy-density polyanionic cathode material.

This method has not only significantly reduced lithium extraction time but has also markedly improved the synthesis efficiency of high-performance battery materials, achieving closed-loop upcycling of ‘waste-to-resource.’ More importantly, the technology has enabled the synergistic utilization of discarded cathode materials and leaching residues—previously considered waste—effectively preventing resource depletion and secondary pollution. This study has provided an innovative pathway for retired lithium battery recycling that is high-value, low-energy, and short-process, making a substantial contribution to advancing battery circular economy.

4. Cell Reports Medicine丨Cracking the Code of Immunotherapy Resistance: An Algorithm-Guided Blueprint for Reversal

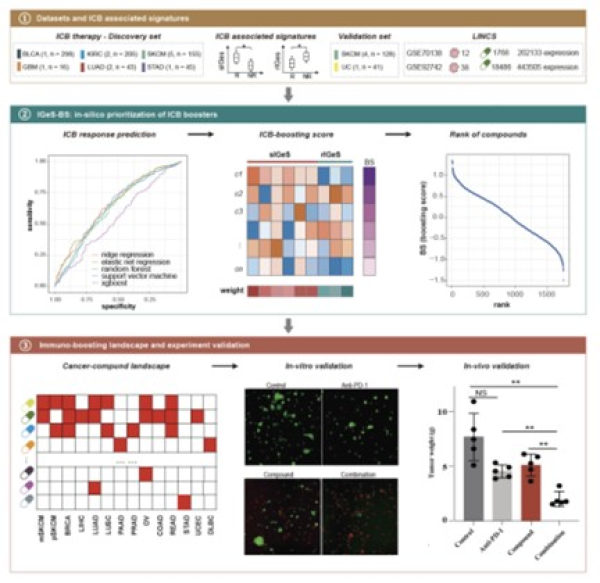

Computational Methodology and Experimental Validation for Screening Immunotherapy Combination Drugs

The LI Hong research group from the Shanghai Institute of Nutrition and Health, Chinese Academy of Sciences, collaborated with HU Bo's team from Zhongshan Hospital affiliated with Fudan University to develop a data-driven computational framework named IGeS-BS. This framework is designed to screen compounds that enhance the efficacy of immunotherapy, providing a new strategy to overcome immunotherapy resistance.

Although immune checkpoint blocking (ICB) therapy has achieved breakthroughs in tumor treatment, drug resistance remains widespread. Current ICB combination strategies with chemotherapy or targeted drugs predominantly rely on empirical attempts, lacking systematic screening methods. To address this, the research team integrated transcriptome data from nearly 1,000 immunotherapy patients, identifying 33 tumor microenvironment features (IGeS) capable of stably predicting therapeutic efficacy. Based on gene expression changes before and after compound perturbation, they constructed a scoring system to evaluate the potential of compounds to enhance immunotherapy.

The IGeS-BS framework has been applied across 13 cancer types, mapping an immune efficacy enhancement atlas that encompasses over ten thousand compounds. This approach has successfully identified multiple synergistic drug candidates. Experimental validation has demonstrated that high-scoring compounds SB-366791 and CGP-60474 can significantly reverse resistance to anti-PD-1 therapy. Furthermore, the combination of SB-366791 with mitoxantrone and PD-1 inhibitors has enhanced therapeutic efficacy in hepatocellular carcinoma, colon cancer, and lung adenocarcinoma.

Collectively, this work provides a computational catalyst for immunotherapy optimization. With the exponential accumulation of single-cell perturbation datasets (e.g., Perturb-seq/CROP-seq), the IGeS-BS architecture is projected to systematically expedite the translation of synergistic mechanisms into clinical protocols.